Apple Uses Tiny QR Codes to Track Display Manufacturing Failures and Cut Costs

Apple etches iPhone displays with small QR codes that let it precisely track the number of defective screens that are thrown out by suppliers, according to a new report from The Information.

One barcode is the size of a grain of sand and can be viewed only with special equipment, while the other is on the inside of the display along the bezel. Apple spent millions of dollars developing the barcode process and installing laser scanning equipment at Lens Technology and Biel Crystal, two manufacturers that make the iPhone's cover glass.

With this system, Apple has a precise count of every piece of glass produced by Lens and Biel, and an exact read on how much material is wasted due to defects. A source that spoke to The Information said that when the barcodes were first implemented, Apple found that as many as three out of 10 pieces of cover glass were thrown away due to manufacturing errors, and with pressure from Apple, the suppliers have been able to cut that down to one in 10. Because Apple pays for production, lowering error rates has saved it hundreds of millions of dollars.

Apple has used the display barcodes to streamline manufacturing since 2020, and the company is able to see which company made the glass and the date it was manufactured for tracking production level and yield rate. Other iPhone components have had small barcodes to trace defects or find the source of leaks for many years, but prior to the display system, barcodes were primarily used for metal parts.

The Information's full report goes into more detail on the barcode, including the complex, multi-step process that Apple uses to get the barcodes onto the displays.

Popular Stories

Apple will adopt the same rear chassis manufacturing process for the iPhone SE 4 that it is using for the upcoming standard iPhone 16, claims a new rumor coming out of China. According to the Weibo-based leaker "Fixed Focus Digital," the backplate manufacturing process for the iPhone SE 4 is "exactly the same" as the standard model in Apple's upcoming iPhone 16 lineup, which is expected to...

Apple typically releases its new iPhone series around mid-September, which means we are about two months out from the launch of the iPhone 16. Like the iPhone 15 series, this year's lineup is expected to stick with four models – iPhone 16, iPhone 16 Plus, iPhone 16 Pro, and iPhone 16 Pro Max – although there are plenty of design differences and new features to take into account. To bring ...

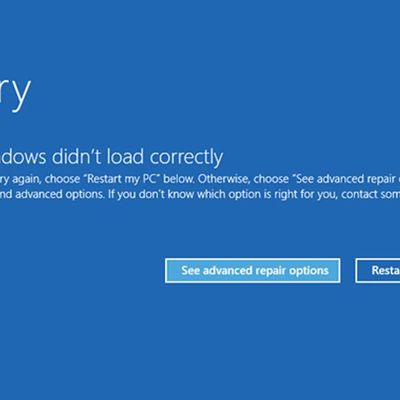

A widespread system failure is currently affecting numerous Windows devices globally, causing critical boot failures across various industries, including banks, rail networks, airlines, retailers, broadcasters, healthcare, and many more sectors. The issue, manifesting as a Blue Screen of Death (BSOD), is preventing computers from starting up properly and forcing them into continuous recovery...

Israel-based mobile forensics company Cellebrite is unable to unlock iPhones running iOS 17.4 or later, according to leaked documents verified by 404 Media. The documents provide a rare glimpse into the capabilities of the company's mobile forensics tools and highlight the ongoing security improvements in Apple's latest devices. The leaked "Cellebrite iOS Support Matrix" obtained by 404 Media...

Apple is seemingly planning a rework of the Apple Watch lineup for 2024, according to a range of reports from over the past year. Here's everything we know so far. Apple is expected to continue to offer three different Apple Watch models in five casing sizes, but the various display sizes will allegedly grow by up to 12% and the casings will get taller. Based on all of the latest rumors,...

If you have an old Apple Watch and you're not sure what to do with it, a new product called TinyPod might be the answer. Priced at $79, the TinyPod is a silicone case with a built-in scroll wheel that houses the Apple Watch chassis. When an Apple Watch is placed inside the TinyPod, the click wheel on the case is able to be used to scroll through the Apple Watch interface. The feature works...